Professional cutting plotters for demanding tasks - expand your business!

Flatbed cutters from CMC Maschinenbau are the ideal addition to existing machinery. Thanks to their flexibility, they also enable the acceptance of smaller orders that could only be produced uneconomically on large die-cutting systems.

From individual display packaging for a short-term sales campaign to seals made of rubber, felt or silicone and the cutting of leather and upholstery fabrics in the furniture industry, there are only a few limits to the possible applications of an industrial cutting plotter. It is also ideal for producing prototypes during product development or for trial orders.

Examples of this include the development of vibration-proof packaging made from cardboard or a technical die-cut part made from a multiple laminate. If, when testing the component, it is determined that there is a need for improvement, the CAD-supported design can be adapted within a very short time and the new electronic data can be converted into a finished die-cut part.

With iEcho cutting plotters, there are far fewer limits to your creativity in the development process, because you don't need a specially made tool for every change.

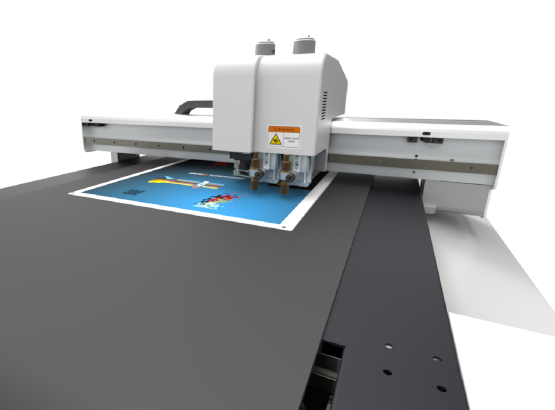

Cutting plotter IECHO PK0705 plus

- Max. Cutting area L x W: 750 mm x 530 mm

- High-precision base frame

- Work table: perforated aluminum plate

- Electric motor

- High-precision guide rails

- Control system

- Compressor

-

Preis: 18.500,00 EUR exkl. MwSt.

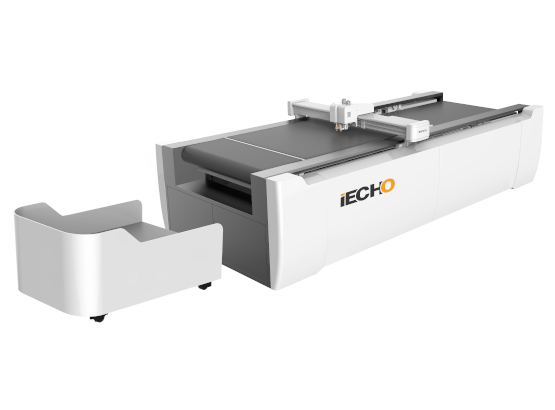

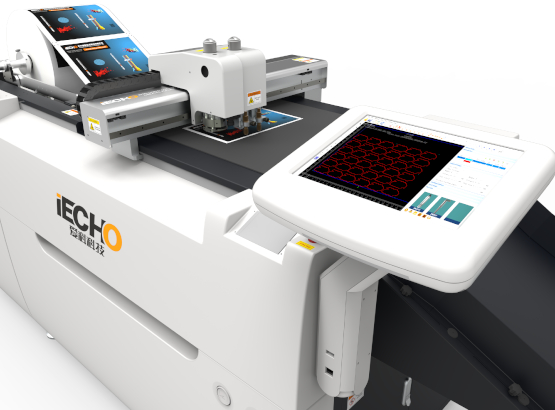

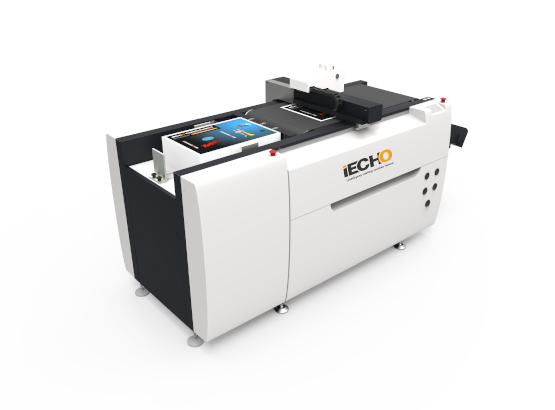

Cutting plotter IECHO PK1209 PRO MAX

- Max. Schnittbereich L x B: 1200 mm x 900 mm

- Drag knife

- Oscillating tool

- Creasing tool

- Perforating tool

- Cutting system for roll material

- Automatic sheet feeder

- Preis: 28.800,00 EUR exkl. MwSt.

You can expect these benefits from a cutting plotter:

Only as much is produced as ordered. The integrated conveyor belt is used to transport the cut or die-cutted material. This eliminates the need for the usual material bridges that are necessary with other die-cutting techniques to transport the die-cutted parts out of the die-cutting area. Depending on the shape and material, the material requirement can be reduced by up to 50%.

Complex contour lines can be cut that are not possible with conventional die-cutting tools (steel rule cutting) (e.g. very close spacing of cuts).

If the same data is also used for the series, there are no deviations due to e.g. incorrect or inaccurate data conversion

...can be produced without the tool costs required for traditional die-cutting techniques. There is no need to wait for the die-cutting tool to be manufactured (time to market).

...such as those created for individualized products or promotional packaging can be produced cost-effectively. The lead time is very short and the cutting options offer virtually no limits to creativity, meaning that very unusual and exclusive packaging is also possible, for example.

The number and quantity of primary materials can also be reduced. Cutting plotters largely manage without run-in material and can be flexibly adjusted to the available material.

...can be available in a roll (roll-to-sheet or roll-to-part) and are processed fully automatically.