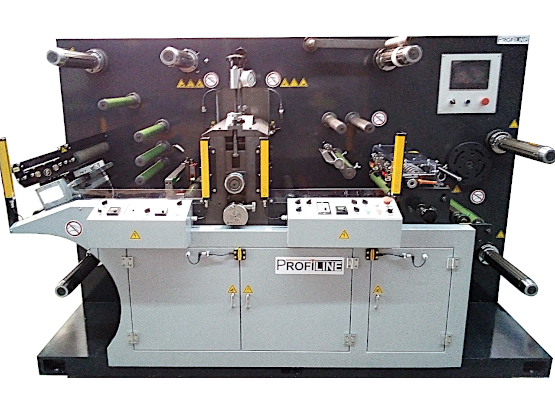

Halbrotative Stanzmaschine PROFIline R-320

Die Halbrotative Stanzmaschine PROFIline R-320 ermöglicht die registergenaue Herstellung von Stanzteilen und Etiketten sowie von Schmalschnittrollen aus beliebigen Rollenmaterialien wie Papier, Folien, Haftetiketten und Laminaten bis 600gr./m². Sie Konfektioniert und Kontrolliert bahnförmige Materialien bis zu einer Breite von 320 mm.

Die aus einem massiven Stahlrahmen bestehende, robuste Maschine lässt sich bereits nach kurzer Einarbeitungszeit problemlos bedienen. Die Geschwindigkeit kann elektronisch geregelt werden. Nach Erreichen einer voreingestellten Anzahl von Etiketten oder Laufmetern stoppt die Maschine automatisch.

Der einfach, effiziente Aufbau der Anlage ermöglicht extrem kurze Ein- und Umrüstzeiten.

Zu verarbeitendes Material: Haftetiketten, Papier, Folie und Laminate bis 600gr./m²

Ausstattung der PROFIline R-320

Stahlplattenkonstruktion

-

Geschweißter Stahlrahmen

-

Seiten und Abdeckplatten aus Stahlblech

-

Elektronik im Maschinengehäuse integriert

-

Anschluss 400 Volt

Abrollung mit pneumatischer Spannwelle

-

Magnetpulverbremse

-

Rechts/links Abwickeln möglich

-

Automatische Bahnzugregelung

-

Abschaltung bei Rollenende

-

Pneumatische Spannwelle 76 mm

-

Durchmesser max. Ø 600 mm

-

Rollengewicht max. 120 kg

-

Materialbreite 100 mm bis 320 mm

Bahnkantenregelung

-

Drehrahmenführung

-

Elektromotorischer Stellantrieb

-

Max. Bahnlagefehler +/- 10 mm

-

Infrarotkantenfühler

-

(Ultraschallkantenfühler auf Anfrage)

Splicetisch

-

Integriert in Bahnlaufregelung

-

Zwei mechanische Klemmen

-

Messerführung für Quer- oder Diagonalschnitt

Halbrotationsstanze

-

Stanzlänge halbrotativ 200mm-450mm

-

Stanzlänge vollrotativ 250mm-550mm

-

Trio Motion Control-System

-

Servomotorisch angetrieben

-

Optischer Registersensor nach Druckmarke oder Label

-

160 Zähne Magnetstanzzylinder

-

1/8 Zoll cp Verzahnung

-

Gegenstanzzylinder

-

Andruckbrücke mit Andrucklagern und Abstreiferfilzen

-

Hydraulische Stanzdruckanzeige

-

Einstellbarer Gitterabzug mit Magnetpulverkupplung und 3 Zoll Spannwelle

-

Ohne Stanzwerkzeuge

Laminierstation

-

Abrollung mit pneumatischer Spannwelle 76 mm

-

Manuell einstellbare Magnetpulverbremse

-

Gummierte Andruckrolle

-

Aufrollung mit pneumatischer Spannwelle 76 mm

-

Manuell einstellbare Magnetpulverkupplung

Vorzugseinheit

-

Stahlwalze

-

Gummierte Anpressrolle

-

Einstellbarer Anpressdruck der Anpressrolle

-

Servomotorisch angetrieben

Längsschneider

-

Scherenschnittsystem

-

Acht Stück Obermesser

-

Acht Stück Untermesser

-

Minimale Schnittbreite 18mm

-

(Andere Schneidsysteme Klinge-, Quetschschnitt auf Anfrage)

2 Stück Aufwicklung

-

Pneumatische Spannwelle für 3 Zoll Hülsen

-

Bahnzug über Magnetpulverkupplung einstellbar

-

Innen- oder Außenwicklung festeingestellt

-

(Umschaltbar auf Anfrage)

-

Rollendurchmesser max. 600 mm

-

Zulässiges Achsgewicht 120 kg

Absaugevorrichtung

-

Axialgebläse zum Absaugen eines Randstreifens

Bedienungs- und Steuereinheit

-

Farbiges Touch-Display (Bedienersprache Englisch)

-

Hauptschalter

-

Steuerung EIN

-

Maschine START / STOP

-

Einrichtfunktion

-

Not-Aus

-

Variable Geschwindigkeit durch Drehpotentiometer

-

Meter- und Etikettenzähler umschaltbar

-

Automatisches Stoppen der Maschine bei Erreichen der vorgewählten Etikettenanzahl

-

Bahnlauf von links nach rechts

-

Bahngeschwindigkeit bis 90m/min bei Rotationsbetrieb, je nach Produkt

-

Bahngeschwindigkeit bis 70m/min bei Halbrotationsbetrieb, je nach Produkt

Technische Daten

-

Elektrische Spannung: 400 Volt

-

Frequenz: 50 Hz

-

Länge x Breite x Höhe ca.:4.300 mm x 1.200 mm x 1.800 mm

-

Gewicht ca.: 3.600 kg