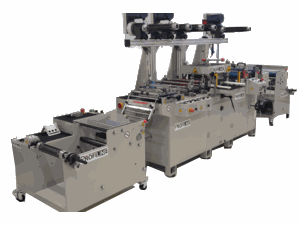

Flachstanzmaschine PROFIline F-320A

Die Flachstanzmaschine PROFIline F-320A ermöglicht die Herstellung von Etiketten und Stanzteilen auf Rolle oder Bögen. Die Flachstanze erreicht eine Stanzgeschwindigkeit bis zu 180 Hübe/min. Durch die 4 Auf- und 4 Abwickler sind auch komplizierte Stanzteil-Konstruktionen möglich.

Zu verarbeitendes Material: Haftetiketten, Papier, Folie, Laminate und Schäume bis 600gr./m²

Bitte stellen Sie vor Auftragserteilung Muster für Stanzversuche zur Verfügung.

Ausstattung der PROFIline F-320A

Gußeisenkonstruktion

-

Maschinenkörper aus massivem Gusseisen

-

Belegt mit lackierten Stahlplatten

-

Seiten und Abdeckplatten aus Stahlblech

-

Elektronik im Maschinengehäuse integriert

-

Separate Abrollung

-

Separate Aufrollung

-

Anschluss 400 Volt

Separate Abrollung mit pneumatischer Spannwelle

-

Magnetpulverbremse

-

Rechts/links Abwickeln möglich

-

Tänzer-Lage-Regelung

-

Automatische Abschaltung bei Rollenende

-

Pneumatische Spannwelle 76 mm

-

Durchmesser max. Ø 700 mm

-

Rollengewicht max. 240 kg

-

Materialbreite bis 320 mm

Separate Abrollung mit pneumatischer Spannwelle

-

Magnetpulverbremse

-

Rechts/links Abwickeln möglich

-

Vorzug durch Stahl- Gummirolle

-

Tänzer-Lage-Regelung

-

Automatische Abschaltung bei Rollenende

-

Schlaufensteuerung

-

Pneumatische Spannwelle 76 mm

-

Durchmesser max. Ø 700 mm

-

Rollengewicht max. 240 kg

-

Materialbreite bis 320 mm

Bahnlaufregelung

-

Manuell am Einzug der Hauptmaschine

-

Zwangsausrichtung der Bahn durch Schlaufensteuerung

2 St. Laminier Station

-

Gummierte Rolle

-

Mitlaufende Stahlrolle

-

Einstellbarer Anspressdruck der Anpressrolle

Registerregelung

-

Sick Druckmarkenleser

-

Voreinstellung der Druckmarke über Touch-Display

-

Registergenauigkeit +/-0,1 mm bei Druckmarke 2x5 mm

-

Ausrichten der Bahn durch verstellen des Lichttasters und Vorzugseinstellung

Flachstanzstation

-

Vier Säulen Hubstanze

-

Stanzlänge bis 350 mm

-

Stanzbreite 300 mm

-

Stanzdruck 2,8 Tonnen

-

Geeignet für Bandstahlschnitte (12 bis 42 mm) oder Magnetplatte

-

Geeignet für komplett Werkzeuge mit 65 mm maximaler Höhe

Aluminiumprofilbrücke

Über der gesamten Länge der Hauptmaschine

Bestückt mit :

-

4 Auf.- bzw. Abwickler

-

Umschaltbar Rechts- Links Lauf

-

1 Gitter Aufwickler für Stanzabfälle

-

5 St. pneumatische Spannwellen

-

Bahnspannung über Potentiometer jeweils getrennt einstellbar

Zähler

-

Hubzähler mit Vorwahlmöglichkeit und Unterbrecherkontakt

-

Bögenzähler mit Autounterbrecher

Bogenschneider

-

Schneidbreite 320 mm

-

Schneidlänger 10-600 mm

-

Längeneingabe über das Touch Screen

-

Ablagetisch

Aufwicklung und Längsschneider

-

Pneumatische Spannwelle für 3 Zoll Hülsen

-

Bahnzug über Magnetpulverkupplung einstellbar

-

Rollendurchmesser max. 700 mm

-

Scheerenschnittwerk

-

Zulässiges Achsgewicht 240 kg

Bedienungs- und Steuereinheit

-

Farbiges Touch-Display (Bedienersprache Deutsch)

-

Hauptschalter

-

Steuerung EIN

-

Maschine START / STOP

-

Einrichthub

-

Schalter für einen Arbeitsgang

-

Not-Aus

-

Variable Geschwindigkeit durch Drehpotentiometer

-

Meter- und Etikettenzähler umschaltbar

-

Automatisches Stoppen der Maschine bei Erreichen der vorgewählten Hubzahl

-

Elektronikkomponenten im Maschinengehäuse integriert

-

Bahnlauf von links nach rechts

-

Geschwindigkeit 20-180 Hub/min

Besondere Wartungsvorschriften

-

Ölwechsel alle 2.000 Betriebsstunden, oder alle 12 Monate

-

Benötigt werden ca. 8 Liter 10 (15) W40

-

Der Ölfilter ist monatlich zu reinigen

Technische Vorschriften

-

Elektrische Spannung: 400 Volt

-

Elektrische Leistung: 4,8 KW

-

Strom: 16 Ampere

-

Frequenz: 50 Hz

-

Hauptmaschine L x B x H ca. 2.100 mm x (850 mm) Aufstellbreite 950 mm x 1.800 mm

(Breite von 850 mm ist erreichbar nach Demontage von Arbeitsplattform vor der Stanze und Steuerpult)

-

Aufwickler: ca. 800 mm x 700 mm x 800 mm

Gewicht: ca. 200 kg

-

Abfwickler: ca. 750 mm x 800 mm x 900 mm

Gewicht: ca. 200 kg